Cooperation to Improve Tooling Machine Development Capabilities in The Industrial Technology Development Center (PPTI) ITB Formally Begins

The development of the manufacturing industry in Indonesia needs to be supported by a strong machine tool industry. The cooperation between the Indonesian and the Republic of Korea government in developing the capability to build machine tools in Indonesia has been initiated to increase the national machine tool industry’s capability so that it can support the national manufacturing industry. This machine tool development program will be carried out at the Center for Technology and Industrial Development (PPTI) located at the Faculty of Mechanical and Aerospace Engineering (FTMD), Institut Teknologi Bandung.

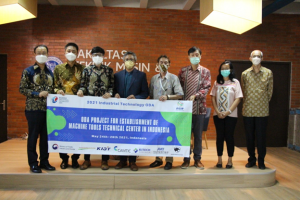

On Friday (28/05), ITB was represented by Prof. Tatacipta Dirgantara, Dean of the Faculty of Mechanical and Aerospace Engineering (FTMD), and Jung Young Doo from CAMTIC (Advanced Mechatronics Technology Institute for Commercialization) officially started a collaborative program to increase the development of machine tools. The event, which was held at the FTMD Library, was also witnessed by Chung Keun Yong, Commercial Attache from the Embassy of the Republic of Korea (South Korea) for Indonesia, Bae Gun Yeol, Director of KITECH (Korea Institute of Industrial Engineering), Bok Dug Gyou, Director of KOTRA (Korea Trade) Investment Promotion Agency), Azhar Fitri, Director of Access to Industrial Resources and International Promotion (Directorate General of Resilience, Territoriality and International Industrial Access (KPAII) Ministry of Industry), along with ranks from the ADIPI Directorate and the Secretariat of DITJEN KPAII, as well as DITJEN ILMATE (Metal Industry, Machinery, Transportation Equipment, and Electronics).

In his words of crisis, Prof. Tatacipta Dirgantara said that the idea of establishing a machine tool development center had been started 10 years ago as a form of ITB’s concern, especially FTMD lecturers, to increase the capacity and quality of machine tools in supporting the manufacturing industry in Indonesia which is increasing every year. Without the ability to develop independent machine tools, the development of national manufacturing industries is highly dependent on other countries because machine tools are the main equipment used in the manufacturing industry. ODA PROJECT FOR THE DEVELOPMENT OF TECHNICAL CENTER MACHINERY IN INDONESIA is a collaborative program that is in line with the spirit of ITB to build a national machine tool industry.

The support for this cooperation was again conveyed by the Government of the Republic of Korea, represented by the Commercial Attaché for Indonesia. Chung Keun Yong said that the South Korean government supports and appreciates the enthusiasm of FTMD in making this collaboration a success. In this cooperation, the Government of Indonesia received equipment grants related to the development of machine tools. Some of the equipment has gradually arrived in Indonesia and is placed and operated in the PPTI-ITB building.

Meanwhile, the Indonesian government, represented by Azhar Fitri, said that this development center was expected to help Indonesia’s manufacturing industry to compete in the world and increase national capabilities to play a role in the global manufacturing supply chain. Although in the last few years the development of Indonesia’s manufacturing industry has begun to be recognized in the world, in the future, the government hopes that the Indonesian manufacturing industry can play a more role in the medical and agricultural equipment industry not only to meet national needs but also to play a role in the global market.

The cooperation worth 5 million dollars, or the equivalent of 70 billion rupiahs, will last for 3 years (2019-2021). Due to the COVID-19 pandemic, this project will extend to December 2022. In addition to grants for equipment to build machine tools, the Korean government will grant 55 sets of NARA manual lathe components assembled at PPTI-ITB and then distributed to various parties for performance testing. Furthermore, some of the important components of these machine tools will be made domestically by involving many local manufacturing industries.

This ODA (Official Development Assistant) project originates from MOTIE (Ministry of Trade, Industry and Energy) South Korea and involves many institutions in one consortium; including KIAT (Korea Institute for Advancement of Technology) as Project’s General Manager, CAMTIC (CAMTIC Advanced Mechatronics Technology Institute for Commercialization) as project operator, KITECH (Korea Institute of Industrial Technology), JIAT (Jeonbuk Institute of Automotive convergence Technology), and Tools Doosan Machine.